One of the questions that we get most often is: "Are your cases made of real wood?". The answer to that is "Yes, we always use real wood veneer". There are many different types of veneer and many misconceptions about whether or not each type is real wood, so we will clear up some of those questions here!

First and foremost, we need to understand how real wood veneer is made.

How Veneer is Made

Preparation.

Once a tree has been selected and cut down, it first needs to be debarked; this is achieved with a machine that carefully scrapes all the bark off of the wood without damaging the core.

After the bark is removed, the entire log needs to be brought up to a high, consistent moisture content in order to soften the wood and prevent tearing during the peeling/slicing process. Steam treatment and soaking are common methods that are used to bring the wood up to the required level. Once steamed, the logs are cut down into the required length for peeling; typically a little over 8 feet if a 4x8 sheet is being made. The cut log is now ready for Peeling:

Peeling

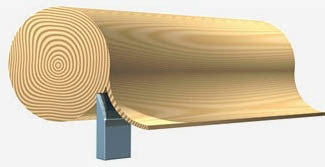

For a type of veneer called "Rotary Cut", the log gets loaded into a veneer lathe, which is a large motorized machine that spins the log against a knife (think: huge apple peeler). The lathe rotates the log, taking off a thin continuous slice as it spins.

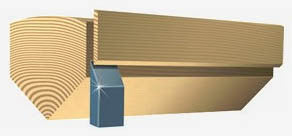

In a different type of veneer, the type we use called "Quarter Cut", the log is loaded into a veneer slicer (this time think: huge deli-meat slicer). The log is run back and forth across the knife to produce thin slices.

Both operations can produce the same thickness and quality of veneer, but the grain pattern varies between the two. We use Quarter Cut for it's linear appearance and it's tendency to expand and contract evenly with environmental changes.

Drying

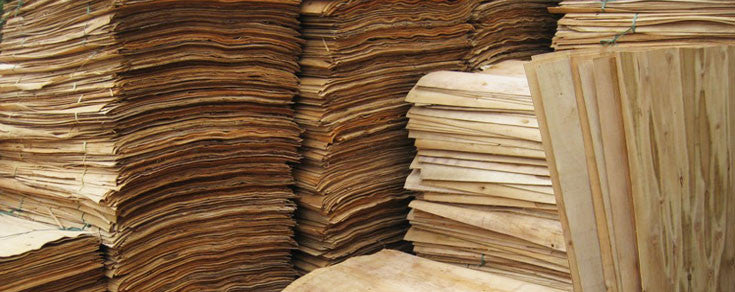

Once peeled or sliced, the veneer is run through a large dryer to ensure that it dries flat and evenly. After drying, the veneer sheets are stacked into bundles.

Clipping and Cutting

The bundles are then clipped to length and cut into consistent widths to prepare them for glue-up.

Gluing

Each trimmed sheet is sent through a gluing machine that bonds them edge-to-edge to produce full 4x8 sheets. For our type of veneer, paperback, the veneer sheets are then bonded to a layer of paper to improve their flexibility and stability.

The sheets are then ready to be sent off to Keyway to be made into cases!

Types of Veneer

Now, this is where things get a little tricky and people can be misled. There are two main types of veneer: One is typically just referred to as "veneer, or natural veneer" and the second is reconstituted veneer which is often called "man-made veneer, recon-veneer, reconstituted veneer, laminated veneer, or eco-veneer".

Veneer

This type of veneer is the real deal. The sheets are made of the wood they are listed as, the colours are true to life, the grain is beautiful, and the price is normally a little higher. This is what we use.

Reconstituted Veneer

First off, recon-veneer is still real wood, but it is often not the type of wood that it is labeled as. The name a recon-veneer is given is the type of wood the veneer has been designed to look like. For example; Reconstituted Ebony is made to look like Ebony, but it is not made of Ebony. This is where people can begin to feel misled.

Typically, recon veneer is made from a type of wood called "obeche" which is lightweight, lightly coloured, and has a consistent grain pattern. These features allow it to be pressed, formed, and dyed to look like a variety of different woods.

Recon veneer can be great because it is easily reproducible, it's consistent, and it's cheaper, but we feel that it also lacks a lot of the authenticity and character of natural veneer.

Below are two examples of Recon vs Natural Veneer.

Recon is on the left, Natural is on the right.

So, as you can see, both types have their place. What's important is that you understand what you are buying. For us, since we are a company specializing in authentic, hand-made, wood products, we will be sticking with natural veneers whenever possible!

4 comments

James

From a millworker’s perspective, this article is very accurate; in nice commercial millwork projects, veneer is a great choice, and often the most premium option for an owner or architect’s design to be built. Veneer is often seen as “cheap” but it absolutely is not; it’s hard to work with and when done well, has an excellent finish.

Frank

Honestly, I’ve made it over 70 years without actually knowing just how veneer was created. This one page not only made it easily understandable, but, now, I can explain the various types of veneer to younger buddies and appear "knowledgeable: :) Thanks!!! This seriously is a well written and explained page.

Jackie Towne

Can’t wait to get my case

Conor Waters

I am so GLAD I have a Keyway phone case. I had a LifeProof case beforehand and there is nothing wrong with it. I’ve just been a fan of real wood phone cases and you guys delivered with amazing designs and reliability. Thank you so much!

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.